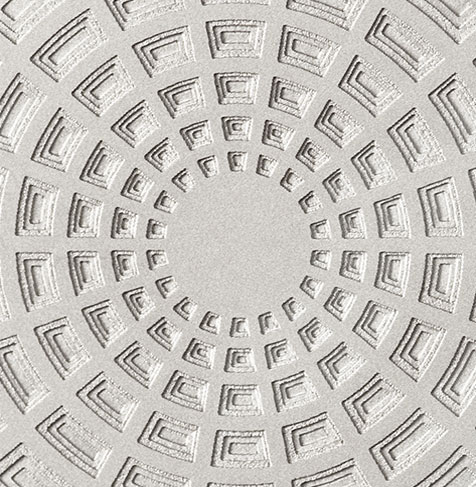

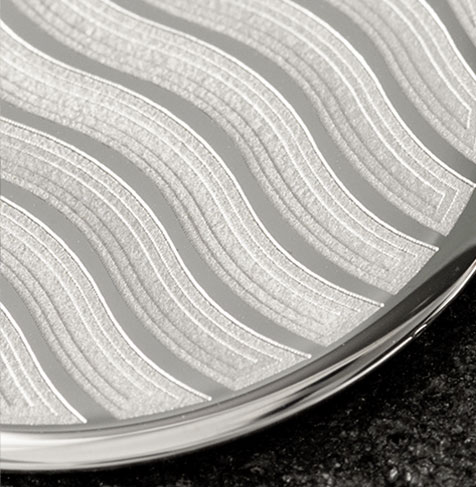

ENGRAVING

Chemical engraving is a technique used to personalise your product. It can be used to add a logo, a décor, text, a number or anything else.

The techniques we use penetrate the metal to a depth of up to 0.2mm and guarantee a perfect finish, whatever the material (gold, steel, titanium, brass, etc.).